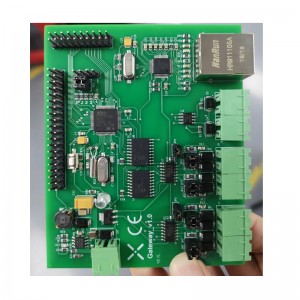

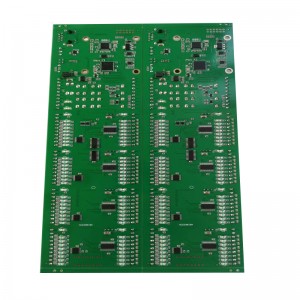

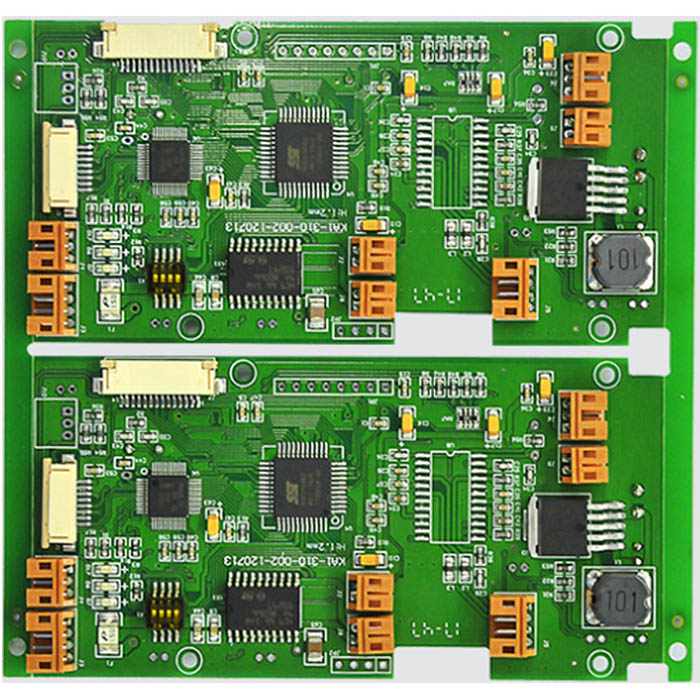

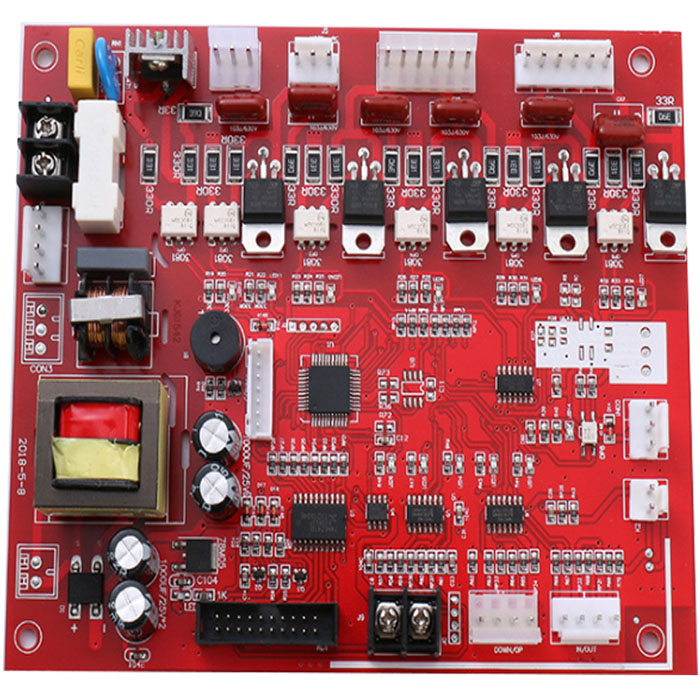

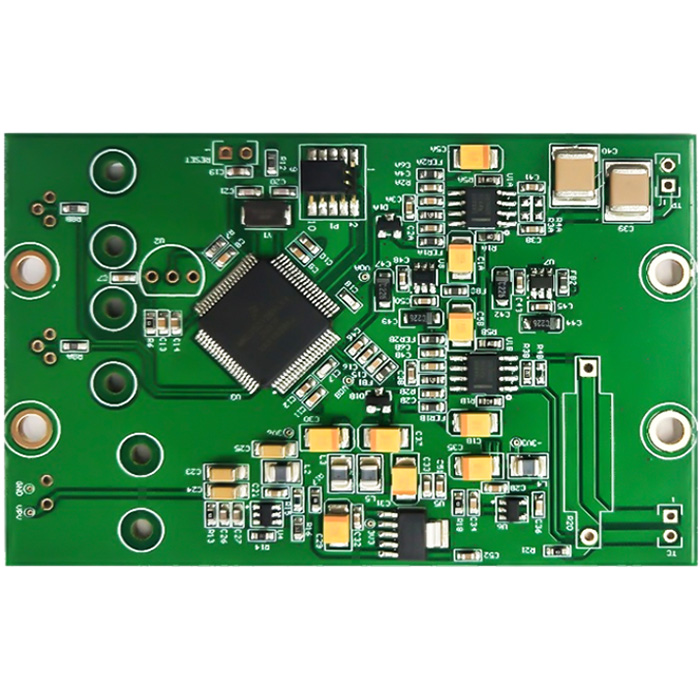

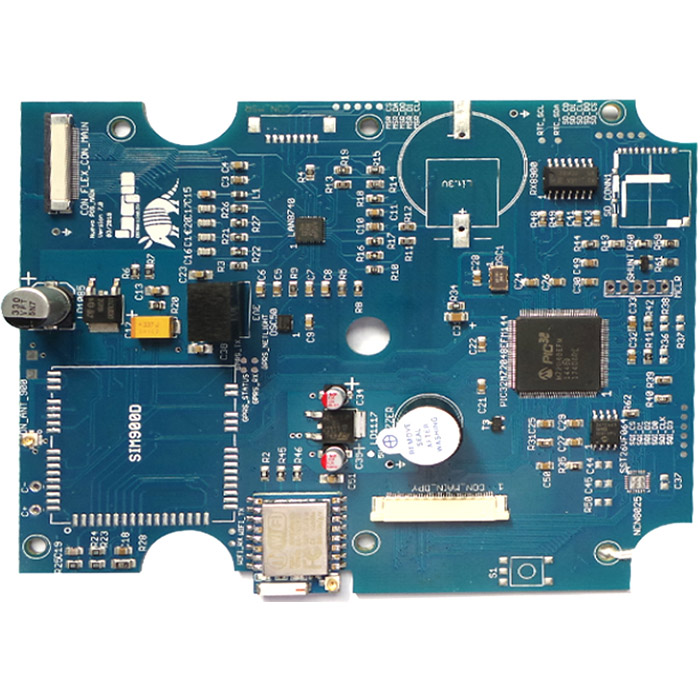

Shenzhen Fast- Speed Turnkey PCB Assembly Electronics Circuit Board Manufacturing With Professional Engineering Servicee

TLHALOSO YA SEHLAHLWA:

| Boitsebiso ba Motheo: | FR4-TG140 | Surface Finish: | HASL(LF) |

| Botenya ba PCB: | 1.6 limilimithara | Mask oa solder: | Botala |

| PCB boholo: | 72 * 120 limilimithara | Silkscreen: | Bosoeu |

| Palo ea Lera: | 2/L | Cu Botenya | 35um(1oz) |

Hobaneng re:

1. Re qetile lilemo tse fetang leshome re sebetsana le ts'ebetso ea elektronike, re e-na le phihlelo e ruileng indastering.

2. Ka thuto e le 'ngoe feela ea seporofeshenale indastering- lebelo le phahameng PCB moralo oa bokhoni bo khethehileng.

3. E ka behoa IC / BGA, sebaka se fokolang sa maoto sa IC 0.25mm BGA sebaka sa bolo ho fihla ho 0.25mm.

4. Tlhahiso ea rona e feto-fetohang, ts'ebetso e phahameng ea lisebelisoa, e ka etsa hoo e batlang e le merero eohle ea lihlahisoa.

Re na le ts'epo ea hore lihlahisoa tsa rona li tla thusa khoebo ea hau le ho ntlafatsa boleng ba hau ho fihlela bo boholo.

| PCBLintho tsa motheo: | FR4, Rogers, Aluminium,Copper-base, PI, PET |

| Lera: | 1-32lera |

| PCBBotenya: | 0.4-3.0mm |

| Botenya ba koporo: | 0.5-3OZ |

| Mask ea solder: | botala, bofubedu, boputswa, bosehla, botsho, bosweu, phereseetc |

| Min.bophara ba mola | 3 mil |

| Min.sebaka sa mohala: | 3 mil |

| Min.bophara ba lesoba: | 0.25 limilimithara |

| Boholo ba boto: | 600 x 1200mm |

| BokaholimoQetella: | HALS/ HALS lead free/ Lesenke la lik’hemik’hale/ Khauta ea lik’hemik’hale/ Khauta e qoelisoang ka metsing/ Immersion Silver Gold/ Osp/ Gold Plating, joalo-joalo |

| Setifikeiti | UL, ISO9001, ISO14001, ROHS, |

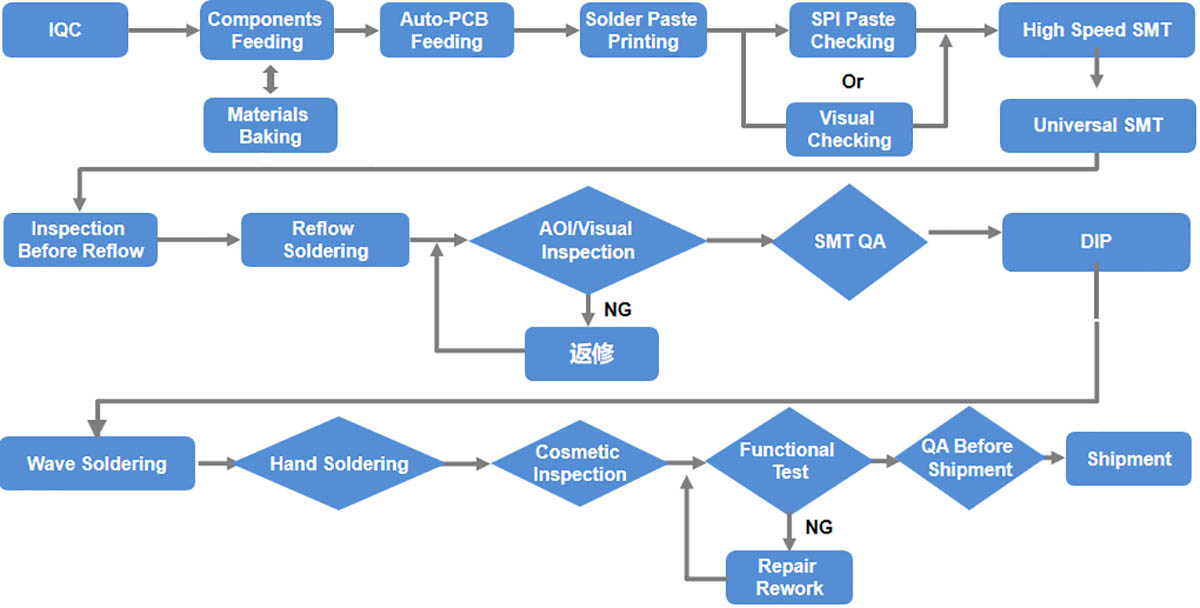

Ts'ebetso ea Kopano ea PCB:

Sehlahisoa sa mantlha:

Mokhoa oa ho laola boleng:

1. Tlhahlobo ea ts'ebetso:

1.1 Netefatsa litlhoko tse khethehileng tsa bareki le litšobotsi tse khethehileng tsa sehlahisoa (ho khona ho palama le ho hanyetsa mocheso oa likarolo tsa sebopeho se ikhethileng)

1.2 Netefatsa hore na data ea tlhahiso ea BOM le PCB e nakong, hore na ho na le lintho tse lokelang ho netefatsoa, joalo-joalo.

1.3 Lekola hore na sebopeho sa PCB (sebopeho se kopaneng sa boto) se ka hlahisoa ka bongata.

1.4 Tekanyetso ea tlhahiso ea mokhoa o khethehileng oa pad board ea PCB board (khauta, OSP, tin ea spray, SMD, NSMD, joalo-joalo).

1.5 Rala mekhoa e fapaneng ea ho bula 'me u khethe lishiti tse fapaneng tsa tšepe bakeng sa li-PCB tse fapaneng tsa ts'ebetso.

1.6 Netefatso le tlhahlobo ea ho tšoaneleha ha likarolo tse nang le sebopeho se ikhethileng le likarolo tse ling tse ikhethileng tse nang le li-pads tsa PCB.

2. Tlhahlobo e kenang (IQC)

Morero oa tlhahlobo: ho thibela ts'ebetso e mpe ea tlhahiso ka lebaka la thepa e futsanehileng le boleng bo sa tšoaneleheng ba lisebelisoa tse nchafalitsoeng moleng ho thibela tahlehelo ea botsofali.

3. Taolo ea likarolo:

Laola thepa le ho laola thepa ka ho arola.

4. Tlhahlobo ea SPI Solder Paste

Morero oa tlhahlobo: fumana khatiso ea solder e sa sebetseng esale pele ho qoba ho phalla molemong o latelang.

5. Tlhahlobo ea AOI

Morero oa tlhahlobo: ho lekola hore na lihlahisoa tse hlahisitsoeng li na le liphoso, li sieo, le lisebelisoa tse mpe tse tsoang ts'ebetsong e latelang.

6. Tlhahlobo ea Sengoloa sa Pele sa SMT

Sepheo sa teko: ho netefatsa ho nepahala ha mokhoa oa tlhahiso ea tlhahiso, ho etsa bonnete ba hore litekanyo tsa karolo ka 'ngoe ea RC li ka har'a mefuta e tloaelehileng.

7. Tlhahlobo ea lihlahisoa tsa IPQC:

Morero oa tlhahlobo: ho etsa tlhahlobo e sa reroang ea lits'ebetso tsohle tsa tlhahiso le hore na li lumellana le litaelo tsa mosebetsi.

8. Tlhahlobo ea pono

Sepheo sa ho hlahloba: ho latela maemo a IPC610D, hlahloba PCBA e holimo-limo e rekisitsoeng bakeng sa liphoso, lintho tse sieo, le likhokahano tsa sebele.

9. X- Ray Welding tlhahlobo

Sepheo sa ho hlahloba: ho hlahloba manonyeletso a solder a pele a sa bonahaleng ka mahlo ho netefatsa ho tšepahala ha bolo e 'ngoe le e' ngoe ea solder ea BGA.

10. QC Manual tlhahlobo

Ho latela maemo a tloaelehileng a tlhahlobo ea IPC- 610, liboto tse felileng lia hlahlojoa, 'me 99.98% ea lihlahisoa tse ntle li netefalitsoe hore li tla romelloa.

11. Tlhahlobo ea ho romela thepa ea QA

Hlahloba ka thata pele o romelloa 'me u hlahlobe khoutu bakeng sa netefatso ho thibela lihlahisoa tse sa tšoaneleheng ho romelloa.

LBH:

1. Bokhoni ba hau ba lihlahisoa ke bofe?

Bokhoni ba rona ke karolelano ea lisekoere-mithara tse 30,000 ka khoeli.

2. Ke na le sampole ea pcb feela, eseng faele ea pcb, na u ka ntlhahisetsa eona?

E, re ka kopitsa faele ho latela sampole ea hau, faele ena e reha mabitso a gerber, 'me tlhahiso e fuoa faele ea gerber.

3. Nako ea hau ea ho etella pele ke efe?

Nako ea ho etella pele hangata e fihla ka nako mona, hangata matsatsi a 5-10 bakeng sa sampole ea PCB, matsatsi a 10-15 bakeng sa tlhahiso ea bongata.Bakeng sa maemo a itseng a khethehileng, re ka boela ra eletsa moreki esale pele ho qoba ho se lebelle kapa tahlehelo ho bareki.

4. Mask ea solder ke 'mala ofe mme ho na le mebala e meng e teng?

'Mala oa rona o tloaelehileng oa mask oa solder o tala.Re ka boela ra fana ka mask a solder ka bofubelu, boputsoa kapa botšo bakeng sa chelete e eketsehileng.